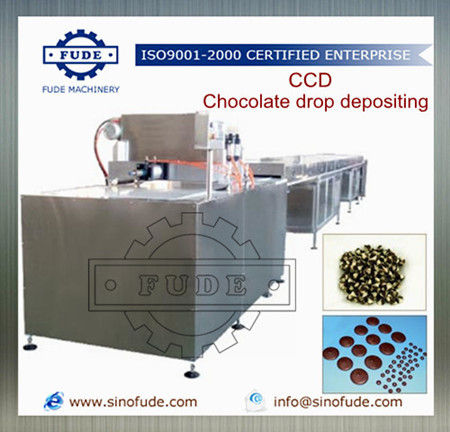

Product Description

Chocolate Drop Depositing Line

Introduce:

- This kind of chocolate drop depositing line is used to produce small chocolate drops.

- It includes the moulding unit and cooling tunnel with chilling unit.

Main parameter:

- Belt width:400-12000mm

- Molding speed:0-15 times/minute

- Cooling temp:0-10"

- The min weight of drop 0.098g

Advanced PLC Touchscreen ControlThe depositing line features a modern PLC control system with a user-friendly touchscreen interface. Operators can easily adjust parameters such as speed, temperature, and drop size, ensuring accurate and consistent results with minimal effort. This enhances productivity and reduces setup time, making it ideal for high-volume chocolate production environments.

Flexible Molding and Capacity OptionsWith its customizable mold trays or belt system, this depositing line accommodates various shapes and sizes, including drops, chips, and buttons. The 60100 liter hopper capacity and adjustable speed (100150 drops/min) allow manufacturers to tailor production according to specific requirements. This flexibility addresses a wide range of confectionery needs.

Efficient Cooling and HygieneThe 8000 mm cooling tunnel maintains a controlled temperature range (5C30C) to ensure perfect texture and consistency of finished chocolates. Made from food-grade PU and stainless steel, the equipment is easy to clean, meeting stringent hygiene standards for food processing while minimizing downtime for maintenance.

FAQs of Chocolate Drop Depositing Line:

Q: How does the PLC touchscreen interface benefit chocolate production?

A: The PLC touchscreen interface allows for precise parameter adjustments, such as temperature, speed, and deposition settings. This makes operation intuitive and helps maintain consistent quality and accuracy, with deposition tolerance up to 1g.

Q: What types of chocolate and molds are compatible with this depositing line?

A: The equipment supports both real and compound chocolate and offers customizable tray or belt molds, making it versatile for producing different shapes and sizes, such as drops, chips, or buttons.

Q: When and where is this chocolate depositing line typically used?

A: This fully automatic line is ideal for large industrial facilities involved in high-volume chocolate or confectionery manufacturing. It is commonly used by distributors, exporters, manufacturers, and suppliers worldwide, particularly in the chocolate, bakery, and snack industries.

Q: What is the process for depositing and cooling the chocolate drops?

A: Chocolate is loaded into the customizable hopper, then deposited accurately via the controlled depositing heads onto trays or conveyor belts. The 8000 mm cooling tunnel ensures uniform cooling from 5C to 30C, yielding perfectly shaped and textured chocolate products.

Q: How does the machine ensure food safety and operational protection?

A: The line is constructed with food-grade materials such as PU and stainless steel. Safety features include an emergency stop button and overload protection, ensuring safe operation and compliance with industrial standards.

Q: What are the benefits of using this depositing line for chocolate production?

A: Key benefits include high production capacity (200500 kg/hour), precise deposition (1g accuracy), customizable operation, fully automated control, and minimized manpower requirements, all contributing to greater efficiency and product quality.