Product Description

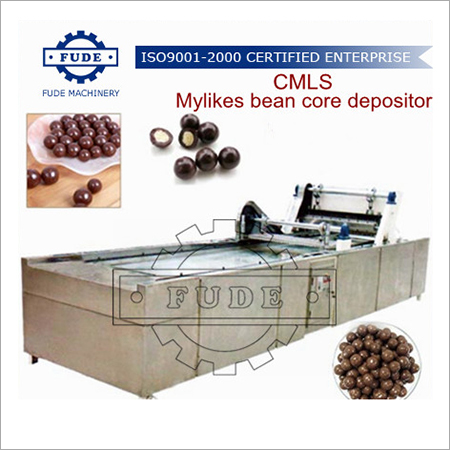

CMLS Mylikes Bean Depositor

Introduce:

Mylikes bean core is made from sugar,milk powder,cocoa powder,maltodextrin,flavor etc,The finished delicious chocolate products shall be coating with chocolate paste.

Main parameter:

- Capacity:Up to 30 strokes/min(50-100kg/h)

Advanced Multi-Nozzle PrecisionBuilt for accuracy and reliability, the CMLS Mylikes Bean Depositor employs a multi-nozzle depositing system to guarantee uniform dosing. The PLC-controlled interface ensures settings are easily adjusted for each confection type, while the food-grade PU conveyor assures safe handling of every batch.

Efficient and Hygienic DesignWith its integrated automatic cleaning system and stainless steel build, the CMLS depositor prioritizes operational hygiene and low maintenance. CE certification and GMP compliance enable safe and efficient production that meets stringent commercial food processing standards.

Versatile Application for Confectionery ProductionThis depositor adapts to a variety of confectionery processes, handling everything from chocolates to nuts. Its adjustable processing pressure and air cooling system support different product requirements, making it suitable for candy manufacturers, exporters, and suppliers worldwide.

FAQs of CMLS Mylikes Bean Depositor:

Q: How does the CMLS Mylikes Bean Depositor achieve high depositing accuracy?

A: The machine uses a multi-nozzle head in combination with a PLC-controlled system, enabling precise dosing with a deviation of less than or equal to 2%. The consistent conveyor speed and adjustable processing pressure also contribute to accuracy.

Q: What cleaning procedures are required for the machine?

A: The depositor features an integrated auto-cleaning system, simplifying sanitation routines. Hot water or steam sterilization can be used, ensuring quick and thorough hygiene with minimal manual intervention.

Q: When is this machine most effectively used in production?

A: The depositor is best utilized during the depositing phase of confectionery lines, particularly in candy, chocolate, and nut coating applications where precise and automated filling is needed for consistent output.

Q: Where can the CMLS Mylikes Bean Depositor be installed, and is support available?

A: The machine is suitable for commercial confectionery and food processing facilities. Installation is provided on-site with service support available to ensure optimal setup and operation.

Q: What products can be processed with this depositor?

A: It is designed for handling Mylikes, beans, dragees, choco-balls, and similar items, making it ideal for various confectionery specialties involving depositing and coating. Its versatility supports diverse production requirements.

Q: How does the touchscreen HMI benefit operators?

A: The easy-to-use touchscreen HMI allows operators to set and monitor all production parameters efficiently, streamline changeovers, and maintain accuracyimproving productivity and reducing training time.

Q: What are the key benefits of choosing this machine for candy production?

A: This depositor offers high precision, fast auto-cleaning, hygienic design, low noise levels, and compliance with CE and GMP standards, ensuring cost-effective, safe, and reliable performance in commercial settings.

Call Me Free

Call Me Free