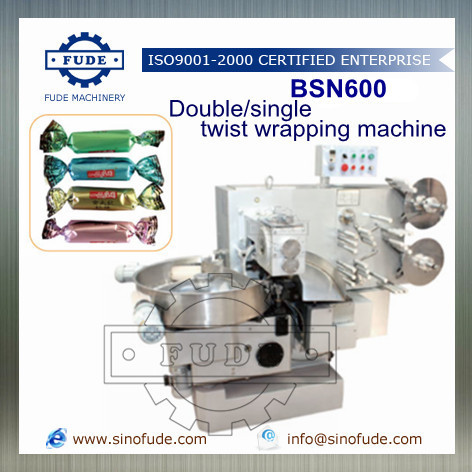

Product Description

Candy Pillow Wrapping Machine is a versatile packing machines used mainly in confectionery industries of all sizes. This machine can be used for packing candies, chicklets and ball gums. This fully automatic machine with SS cladding is easy to operate. It comes with continuous motion mechanism and requires less maintenance. A variety of wrapping material can be used in the machine for wrapping candies of several shapes, designs and sizes. The candy shapes can range from rectangular, square to any special shape. The touch screen on the machine shows working status, faults and instructions. Candy pillow wrapping machine is an ideal machine for rapid packing of candies.

Introduce: The machine is used for pillow type wrapping the Square, spherical, cylindrical, button shape, ellipse and various irregular shapes candies.

Main parameter:

- Materials for wrapping: BOPP,CPP PET metallized film ,Al-Plastic film etc..

- Paper cutting length: 50~100mm base on blades quantity.

- Packing width: 50~180mm

- Power: 220V/3.7kW

- Machine Size: 2900x1350x1550mm

- Weight: 980kg

Advanced Candy Packaging EfficiencyUtilizing state-of-the-art PLC control and a stainless steel slat conveyor, this machine ensures rapid, uniform wrapping of candies. The automatic operation with a single operator required streamlines workflow and improves productivity. Its low noise output and sturdy construction make it a reliable component in any food industry production line.

Precision and Safety GuaranteedFeaturing a PID temperature controller and touch screen interface, operators can easily adjust settings for perfect sealing with every pack. Comprehensive safety systems, including emergency stop and overload protection, safeguard personnel and equipment throughout high-speed operations.

Versatile and Customizable DesignThe Candy Pillow Wrapping Machine accommodates a variety of candy sizes and types thanks to its adjustable guides and customizable filling range. Suitable for distributors, exporters, and manufacturers, its designed to meet the evolving needs of modern confectionery packaging while maintaining hygiene standards and product integrity.

FAQs of Candy Pillow Wrapping Machine:

Q: How does the candy pillow wrapping machine operate?

A: The machine utilizes an electric drive and PLC control system to automate the wrapping process. Candies are placed on the stainless steel slat conveyor, guided through adjustable guides, and then wrapped using a flow pack technique. The PID temperature controller maintains optimal sealing conditions for consistent results.

Q: What types and sizes of candies can be packaged with this machine?

A: This wrapping machine is designed with adjustable guides and a customizable filling range, enabling it to accommodate a variety of candy shapes and sizes within the maximum film width of 220 mm. Its suitable for assorted confectionery products in the food industry.

Q: When is it necessary to use the emergency stop feature?

A: The emergency stop should be used whenever there is a potential safety risk or abnormal machine behavior, such as a jam or an unexpected movement during operation, to immediately halt all machine functions for safe intervention.

Q: Where can this machine be integrated?

A: This pillow wrapping machine fits seamlessly into food processing lines, confectionery plants, or packaging units operated by manufacturers, distributors, exporters, or suppliers. Its compact 4200 x 900 x 1500 mm dimensions allow for flexible placement in most industrial settings.

Q: What are the primary benefits of using this wrapping machine for candy packaging?

A: Key benefits include high efficiency, hygienic packaging, low operational noise, sturdy stainless steel construction, and safety features such as overload protection. These advantages enhance productivity while ensuring product quality and operator safety.

Q: How does the touch screen interface assist the operator?

A: The touch screen interface allows operators to easily set, monitor, and adjust all key machine parameters such as wrapping speed, temperature, and pack length. This user-friendly system streamlines control and facilitates quick changeovers between packaging requirements.

Q: What maintenance is needed for stable machine performance?

A: Regular maintenance should include cleaning the conveyor and sealing elements, checking electrical connections, and ensuring the stainless steel surfaces remain corrosion-free. Following the manufacturers service guidelines helps maintain high performance and prolongs machine longevity.