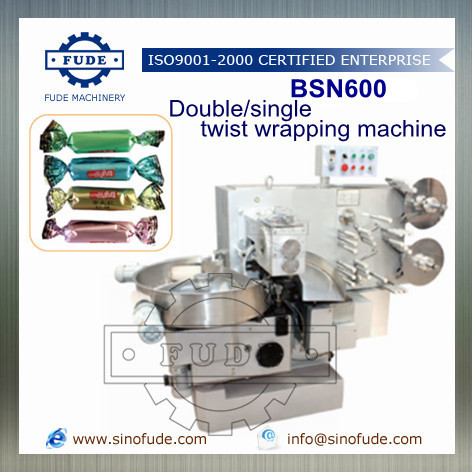

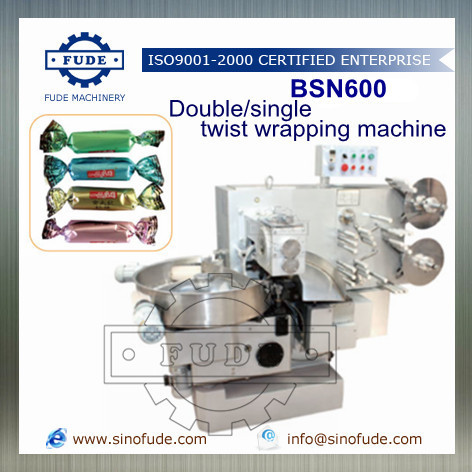

Product Description

Double (single) Twist Wrapping Machine

- Materials for wrapping: PVC, OPP, PET etc..

- Speed: 10-600pcs/min

- Product size: length 12~32mm; width:12~26mm;height: 6~20mm

- Power: 380V/2.5kW

- Machine size: 1900x1000x1750mm

- Weight: 1050kg

High-Speed, Flexible PackagingWith a wrapping capacity ranging from 2500 to 3500 pieces per hour, this machine is engineered for productivity. Quick-change parts reduce downtime, allowing for seamless transitions between various product sizes within 20 mm x 20 mm to 60 mm x 35 mm wrappers. The double (single) twist wrapping style offers adaptability to diverse confectionery shapes and packaging preferences.

Advanced Control and Safety MechanismsEquipped with an intelligent PLC-based control system, the machine ensures precision and consistency across every operation. Operator safety is prioritized through built-in emergency stop buttons and overload protection. Its heavy-duty induction motor guarantees steady performance under demanding factory conditions, and the interface remains intuitive for skilled operators.

User-Oriented Design for Industrial ApplicationsThe stainless steel construction resists corrosion and simplifies cleaning, making this machine ideal for continuous use in industrial environments. Automatic or manual lubrication extends machinery lifespan, while the robust build withstands the rigors of confectionery production. Installation support is available upon request, ensuring smooth integration into existing packaging lines.

FAQs of Double (single) Twist Wrapping Machine:

Q: How does the Double (Single) Twist Wrapping Machine accommodate various candy sizes and shapes?

A: The machine supports a wide product size range within the specified wrapper limits of 20 mm x 20 mm to 60 mm x 35 mm. Quick-change parts and minimal changeover time allow operators to adapt the settings efficiently for different shapes and sizes, ensuring seamless packaging for both candies and toffees.

Q: What materials can be used as wrapping film on this machine?

A: You can utilize several types of wrapping film material, such as cellophane, foil, BOPP, and laminated films. This flexibility enables you to choose the most suitable packaging based on product requirements and market preferences.

Q: When should lubrication be performed on the machine, and is the process automated?

A: Lubrication can be managed either automatically or manually, depending on your operational preference. Regular lubrication ensures smooth operation and extends the lifespan of moving components, especially during continuous, high-capacity production cycles.

Q: Where can installation service be obtained for this wrapping machine?

A: Installation service is available on request through the distributor, exporter, manufacturer, supplier, or trader in India. This ensures the machine is properly set up and integrated into your production line, minimizing downtime and operational issues.

Q: What is the process for changing the wrapping style from double twist to single twist?

A: Changing the wrapping style is streamlined with quick-change parts designed for minimal downtime. Operators can swiftly switch between double and single end twist styles through the user-friendly interface and adaptable mechanical settings, allowing for flexible packaging without complex procedures.

Q: How does the machine ensure operator safety during operation?

A: Safety is addressed through features such as an emergency stop button and overload protection system. These mechanisms help prevent accidents and equipment damage in the event of unusual operating conditions, keeping operators secure while maintaining productivity.

Q: What benefits does this wrapping machine offer to industrial confectionery producers?

A: The machine delivers efficient, high-precision wrapping with low maintenance needs, reducing operational costs and enhancing productivity. Its robust construction, customizable settings, and computerized control make it ideal for industrial-scale packaging of various candies and toffees.