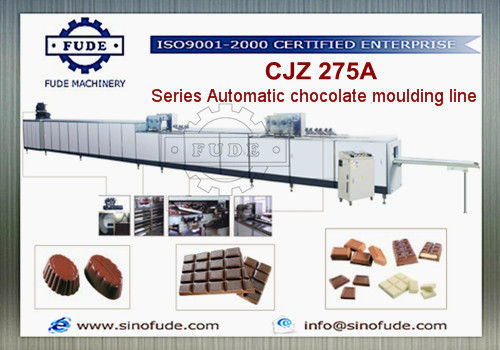

Product Description

Small Chocolate Moulding Machine

Introduce:

A very compact table-top machine that is ideal as an entry-lever or secondary machine for chocolatiers or for a small patisserie or pastry kitchen.It is also perfect as a demonstration machine as it is relatively light abd portable.

High Efficiency with User-Friendly OperationThis chocolate moulding machine stands out for its high efficiency and intuitive manual control panel, ensuring smooth operation even for novices. Designed for convenience, it boasts detachable parts for easy and hygienic cleaning, making it a smart choice for busy environments like bakeries and artisanal chocolate shops.

Robust Design for Consistent QualityConstructed from durable food-grade stainless steel, the machine is engineered to withstand heavy usage. Its integrated cooling tunnel, adjustable conveyor belt speed, and electric heating system help you maintain strict quality control, ensuring consistent size and texture in each batch of chocolates.

FAQs of Small Chocolate Moulding Machine:

Q: How do I clean the Small Chocolate Moulding Machine after use?

A: The machine features detachable parts, making it easy to disassemble and clean thoroughly. Always ensure the unit is switched off and unplugged before beginning the cleaning process for safety.

Q: What types of environments is this machine suitable for?

A: With its compact and floor-mounted design, the machine is ideal for small-scale chocolate production in shops, bakeries, and boutique factories. Its low noise level and manageable size facilitate seamless integration into such settings.

Q: What is the process for moulding chocolate using this machine?

A: Chocolate is poured into the moulds, which are then transported through the machine on an adjustable conveyor belt. The finished pieces are cooled in the integrated cooling tunnel before easy removal and packaging.

Q: When should I use the emergency stop button?

A: The emergency stop button should be used immediately if any unsafe situation arises or if the machine malfunctions. This feature helps ensure the safety of operators during production.

Q: Where should the air compressor be installed for optimal operation?

A: An air compressor with a pressure of 0.8 MPa is required. Place it close to the machine to ensure efficient air delivery and optimal performance.

Q: What are the benefits of the machines stainless steel construction?

A: The food-grade stainless steel ensures the highest standards of hygiene, durability, and resistance to corrosion, making it suitable for continuous use in food production environments.

Call Me Free

Call Me Free