Product Description

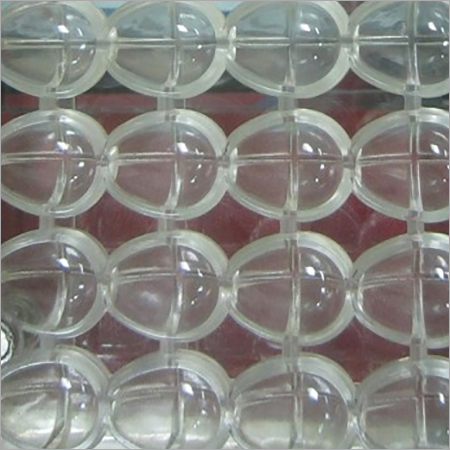

3D Chocolate moulds

3D Chocolate Molds can utilized with chocolate, ganache, caramel, jam, praline and hard confection to make proficient treat every single time. Made of sustenance review silicone, the Truffly Made molds kills the requirement for hand-moving sparing time and work, and are easy to utilize and simple to clean. Contingent upon the sweet size there might be one or numerous pits in the 3D Chocolate Molds. The individual shape depression pieces should be expelled from the form. With scissors, cut the pieces out of the form leaving some level surface all around the edge of the 3D Chocolate Molds. While the chocolate in the primary piece is as yet fluid, put the inverse piece so the parts line up together. With fastener cuts clasp the two parts together.

Key Features:

- Utilize an adequate number of clasps so the level surfaces

- Are in secure contact with each other the distance around

- To keep up the space between cuts

- Used to make a completed three dimensional chocolate pieces

The glossy, smooth finish of our chocolate moulds ensures that chocolates are easily released after setting, resulting in exquisite, professional-quality shapes every time. With minimal sticking and low residue, your creations maintain a pristine, consistent appearance with every use.

Durability and Precision in Chocolate CraftingMade from high-grade polycarbonate, our moulds provide excellent durability and temperature resistance up to 120C. Their precise tolerance of 0.02 mm provides uniformity and consistency across multiple cavities, enabling flawless repetition whether youre crafting in a bakery, kitchen, or confectionery workshop.

Versatile Application for All CreatorsThese moulds cater to the needs of chocolatiers, bakery professionals, and home users. Their robust construction and manual demoulding design make them a reliable choice for producing unique 3D chocolates on any scale. The transparent material also allows for easy monitoring during the chocolate setting process.

FAQs of 3D Chocolate moulds:

Q: How do I use the 3D chocolate moulds for optimal results?

A: To achieve the best chocolate shapes, pour tempered chocolate into the clean, dry mould and tap gently to remove air bubbles. Allow the chocolate to set fully before manual demoulding. The glossy finish helps chocolates release easily and maintain a smooth exterior.

Q: What maintenance steps are recommended to prolong the moulds lifespan?

A: Although our moulds are dishwasher safe, we recommend hand washing with mild soap and soft cloth to prevent scratches and extend their lifespan. Proper care ensures you can achieve over 1000 uses and maintain high-quality results for 2-3 years.

Q: When should I consider replacing my chocolate mould?

A: Replace the mould if you notice significant wear, scratches, or loss of surface gloss, as these may affect chocolate release. Typically, with regular care, the mould will last up to 2-3 years or 1000+ uses.

Q: Where can these moulds be used effectively?

A: These moulds are suitable for professional chocolatiers, bakeries, and home kitchens. Their robust material and standard size ensure versatility, making them applicable for both small- and large-scale chocolate production.

Q: What benefit does the polycarbonate material offer over other mould bases?

A: Polycarbonate is food-grade, lightweight, and extremely durable. It provides superior clarity for monitoring, high heat resistance, precise shaping, and a smoother release compared to silicone or metal alternatives.

Q: How does manual demoulding benefit chocolate production?

A: Manual demoulding allows for better control and reduces the risk of damaging intricate chocolate designs. The moulds glossy surface and precision manufacturing aid in effortless release, preserving the integrity and appearance of your chocolates.

Call Me Free

Call Me Free