Product Description

Automatic biscuit combine sandwiching with packing machine

- BJX-P Automatic biscuit combine sandwiching with packing machine

- This automatic machine is combined the function of sandwiching and flow packing, different sandwiching and packing type is available in this system as option.

Technical specification

- Capacity30~200 sandwiches/min.

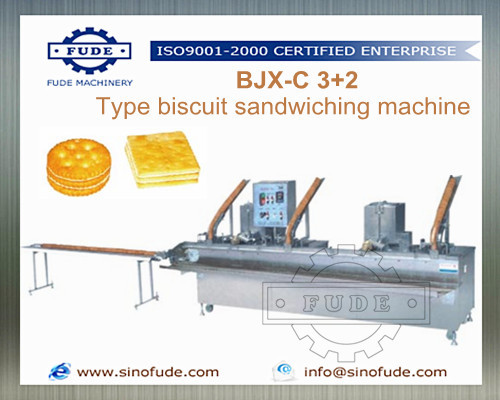

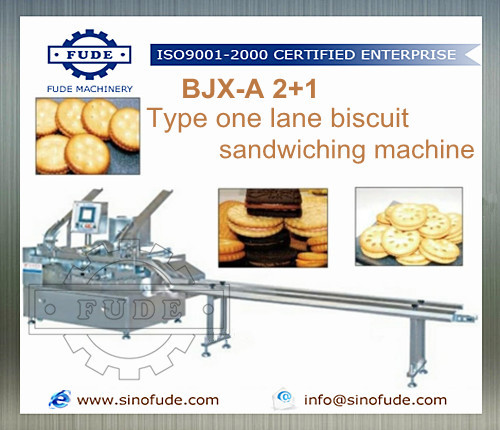

- Biscuit size: Round (35~60mm, H:3~7mm); Square (LxW: 35~60mm; H:3~7mm)

- Power220V/50HZ/7kW; Machine size: 6000x1000x1500mm

Precision Sandwiching and Packing EfficiencyExperience seamless biscuit sandwiching and pillow pack wrapping in a single automated system. With filling accuracy up to 1.5 g and a robust stainless steel conveyor, the machine assures consistently uniform, high-quality productsmaximizing productivity and minimizing manual intervention. Changeover between different products can be completed in as little as 30 minutes, supporting dynamic production needs.

Customizable for Diverse Production RequirementsChoose from one to four customizable lane configurations to match your plants output needs. Supported films include OPP/CPP, OPP/PE, and CPP, catering to various packing preferences. The machine effortlessly handles different cream typeschocolate, vanilla, fruit, and specialty blendsmeeting a broad array of market demands with high flexibility.

User-Friendly and Safe OperationThe system features a touchscreen PLC control panel, ensuring intuitive operation and swift adjustments. Comprehensive safety featuressuch as an emergency stop, protective guards, and overload safeguardpromote operator confidence while maintaining high-speed production. Automatic lubrication reduces maintenance effort, extending machine lifespan and reliability.

FAQs of Automatic biscuit combine sandwiching with packing machine:

Q: How does the machine ensure accurate biscuit sandwiching and packing?

A: The machine employs a high-precision filling system with 1.5 g accuracy, controlled by a programmable logic controller (PLC). The automated stainless steel conveyor and rotary cutter maintain consistent biscuit alignment, ensuring each sandwiched product is precisely packed in pillow-style pouches.

Q: What is the process for changing products or pack sizes on the machine?

A: Product changeover is streamlined for efficiency. Depending on the product and pack size, the changeover typically takes approximately 30 minutes. Adjustments, such as lane configuration or pack length (ranging from 65 mm to 250 mm), are easily managed via the touchscreen PLC control panel, minimizing downtime.

Q: When should the machines automatic lubrication system be checked or maintained?

A: The automatic grease lubrication system is designed for hands-off operation, but periodic inspection is recommended per your maintenance schedule. Routine checks ensure the lubrication system is functioning properly, thereby prolonging the life of critical moving components and maintaining stable performance.

Q: Where can this sandwiching and packing machine be used most effectively?

A: This machine is optimized for industrial biscuit manufacturing plants, particularly in facilities requiring high-speed, continuous production. Its versatility and robust build make it suitable for distributors, exporters, manufacturers, suppliers, and traders seeking efficient production of sandwiched biscuits in China and beyond.

Q: What are the main benefits of using this fully automatic biscuit sandwiching and packing machine?

A: Key advantages include high production speed, minimized labor requirements, uniform sandwiching and packing quality, and reduced operational noise (<75 dB). The customizable design aligns with diverse manufacturing requirements, and the integrated safety features enhance both efficiency and workplace safety.

Q: How is operator safety ensured during machine operation?

A: Operator safety is prioritized through multiple mechanisms, including an emergency stop button, protective physical guards, and an overload safeguard. These features are integrated throughout the system to prevent accidents and protect personnel during routine operation and maintenance tasks.

Call Me Free

Call Me Free