Product Description

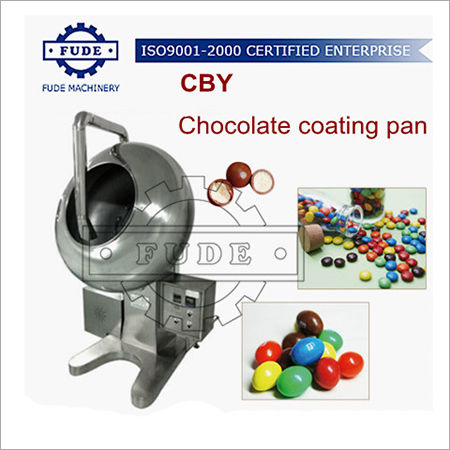

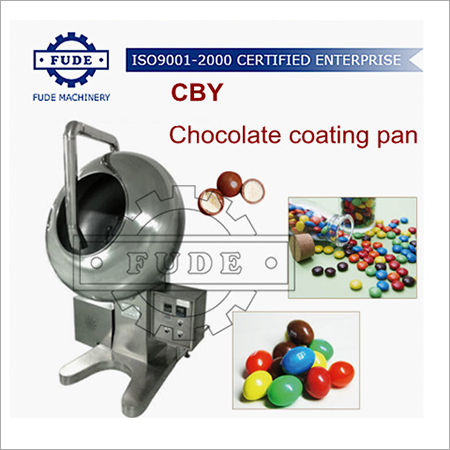

CBY1000 Chocolate coating pan

Introduce:

The coating pan is used for coating and polishing chocolate,syrup,wax etc on grains products.

Main parameter:

| MODEL | CBY1000 |

| Diameter(mm) | 1000 |

| Capacity(kg/batch) | 50-70 |

| Rotary speed(r/min) | 32 |

| Motor power(kw) | 1.1 |

| Fan power(kw) | 0.15 |

| Heater power(kw) | 2 |

Versatile Coating PerformanceThe CBY1000 excels in chocolate coating, glazing, sugar panning, and tablet polishing, making it suitable for a wide array of applications. Its adjustable drum tilt angle and semi-automatic control allow for fine-tuned operation, while the spacious pan accommodates large batches and ensures uniform results.

Durable and Hygienic ConstructionCrafted from polished stainless steel, this coating pan offers corrosion resistance and meets stringent hygiene standards. The easy-to-clean design, paired with manual washing and optional sterilization methods, ensures product safety and regulatory compliance for pharmaceutical and food-grade operations.

Safety and Operational EaseEquipped with overload protection and a safety cover, the CBY1000 prioritizes operator safety. Manual controls and tilting drum discharge streamline the coating process, while quiet operation and a practical floor-mounted installation support efficient workflows in industrial settings.

FAQs of CBY1000 Chocolate coating pan:

Q: How does the CBY1000 Chocolate Coating Pan ensure uniform coating of products?

A: The CBY1000 utilizes a 1000 mm diameter rotary drum operating at 28 rpm, which gently tumbles and coats products such as candies, nuts, and tablets. The adjustable 30 drum tilt facilitates even distribution for consistent coverage during the coating process.

Q: What is the recommended usage environment for this coating pan?

A: This machine is designed for indoor use in environments with temperatures between 10-40C and humidity levels below 80%. Proper conditions help maintain product quality and optimize machine performance.

Q: When should the pan be cleaned, and what cleaning method is used?

A: The pan should be cleaned after each production cycle or batch change to maintain hygiene. Cleaning is performed manually, and optional sterilization using hot air or chemical agents is available for stringent sanitation requirements.

Q: Where is the CBY1000 typically installed in a facility?

A: The CBY1000 is floor mounted and positioned in production areas of pharmaceutical, food, candy, and confectionery facilities where chocolate coating, tablet polishing, or sugar panning processes are required.

Q: What safety features are included in the CBY1000 Coating Pan?

A: The CBY1000 is equipped with overload protection and a safety cover for the pan, offering enhanced operator safety during operation and helping prevent accidental injury or equipment damage.

Q: How is the discharge process managed for coated products?

A: The tilting drum discharge mode allows users to tilt the drum for efficient and controlled removal of finished products, minimizing handling time and ensuring easy material transfer.

Q: What are the main benefits of using this machine for coating applications?

A: Benefits include high production capacity (up to 1000 kg/h), hygienic operation, corrosion-resistant construction, straightforward manual controls, and versatile application for various coating and polishing processes within the pharmaceutical and food industries.

Call Me Free

Call Me Free