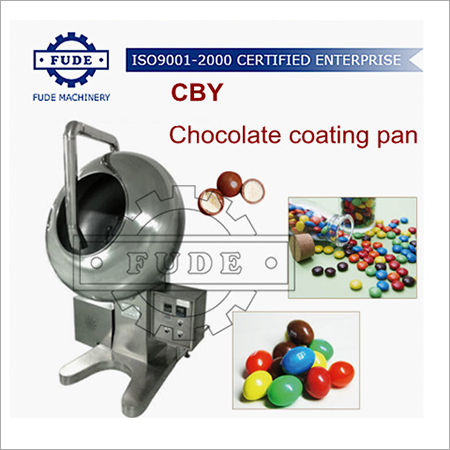

Product Description

Chocolate Coating Machine

Technical Features It is the large-tonnage machine to produce the chocolate mylikes and chocolate bean, and the products are made from peanuts, fudge, raisin. Advantages: advanced DTG polishing device, and the machine is programming auto-controlled, and the man-machine interface is more intuitive, because of the characteristic and colorful touch screen, the operator is able to control the whole producing process. With varied product specifications and large output, this machine is the ideal one to replace the polishing pot. control systemWeinview man-machine interface, and the Siemens 57-300 drive system 4 step cone gear motor of the Delta transducer material conveying system vaned chocolate pump, programming controlling the feeding time main

Technical specifications

CBY400 Chocolate Coating Pan is utilized in confectionery processing, pharmaceuticals, and chemical industries. It is required for coating chocolate syrup, sugar, liquid medicines, & caramel to gems, cookies, biscuits, raisins, almonds, nuts, & cashews. This machine has the diameter of 400 mm with the production capacity of 5 kilograms per batch. It mainly consists of a motor, steel pan, worm & screw driving system, operating panel, and a heater.

Technical specification

MODEL | CBY400 |

Dianmeter(mm) | 400 |

Capacity(kg/batch) | 5 |

Rotary speed(r/min) | 46 |

Motor power(kw) | 0.37 |

Fan power(kw) | 0.15 |

Heater power(kw) | 0.75 |

Uniform and Reliable Coating PerformanceWith its robust SS304 food-grade stainless steel pan, the cc Chocolate Coating Pan provides a uniform finish, ideal for chocolate coating, polishing, and processing a wide range of confectionery products. The mirror-polished drum ensures easy release and cleaning, while a fixed or adjustable 28 RPM speed delivers reliable outcomes. Optional features such as blower heating and timer controls offer customizable operation.

Versatile Options and Easy MobilityAvailable in both manual and semi-automatic models, this pan accommodates a diverse range of batch sizes (10-100 kg). Its well-designed structure features a simple on/off switch and optional timer, fitting seamlessly into confectionery environments. Mounted on durable casters, it can be repositioned effortlessly, offering flexibility on the production floor.

Durable Construction for Professional UseEngineered with robust materials and high-quality finishing, the pan guarantees a long lifespan and minimal maintenance. The air cooling system facilitates consistent product quality while keeping energy consumption low. Its stainless-steel build ensures food safety, rust resistance, and compliance with industrial hygiene standards.

FAQs of cc Chocolate Coating Pan:

Q: How does the chocolate coating process work with this pan?

A: Raw centers or products are placed into the round, SS304 food-grade pan. As the pan rotates at 28 RPM, coating material (such as chocolate or syrup) is gradually added. The consistent motion ensures even distribution and smooth coating. The optional blower heater aids in drying, and the air cooling fan helps set the coating, delivering professional results.

Q: What are the usage benefits of this Chocolate Coating Pan?

A: Users benefit from its uniform coating capability, robust construction, easy-to-operate controls, and customizable batch capacity. Its mirror-polished interior allows quick clean-ups, and the caster-mounted design provides flexibility for repositioning. It is suitable for coating chocolate, candies, tablets, and sweets in a professional environment.

Q: When should I choose the manual or semi-automatic model?

A: Select the manual model for hands-on operation where batch control is needed. Opt for the semi-automatic model if you require features such as a timer control for enhanced process consistency and reduced labor intervention, especially for larger batches or continuous production.

Q: Where can this coating pan be installed in my facility?

A: The pan is floor-mounted, with dimensions of 950 x 780 x 1200 mm for the standard model. Its design allows for installation in chocolate, candy, or confectionery production areas where easy movement and access to electrical connections (220-240V, 50Hz) are available.

Q: What is the recommended cleaning process for the pan?

A: Cleaning is manual and straightforward. Once the coating is complete, the pan can be washed with standard non-corrosive cleaning agents and water. The smooth, mirror-polished surface prevents residue buildup, ensuring quick maintenance and long-lasting hygiene.

Q: How does the pan handle cooling and heating requirements during operation?

A: An integrated air cooling fan is fitted for rapid cooling of coated products, helping to set the coating efficiently. An optional blower heater can also be added if drying between layers is required during the coating process, providing versatility for different product recipes.

Call Me Free

Call Me Free