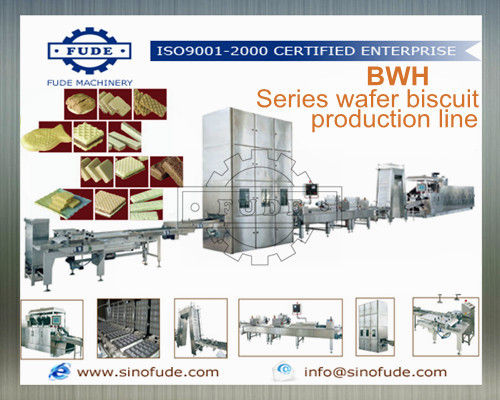

Product Description

Wafer Stick Production Line Egg Roll Machine

BWHJ 100/200 wafer stick production line Egg roll machine

The flow chart of the processing is:

Slurry mixing, Slurry feeding, Baking, filling, roll forming, cutting, cooling conveying, collecting and packing

Specifications:

- Capacity: 20~30kg/h (for hollow roll), 50~60kg/h (for filled roll)

- Diameter of the heating drum: 1800mm

- Gas consumption: 3~5kg/h, or 45kW (with electrical heating)

- Shell size of the machine: 3700 x 1700 x 2500mm

- Weight of the machines: 5000kg

High-Efficiency, Large-Scale OutputDesigned for industrial use, this egg roll machine can produce up to 12,000 wafer sticks per hour, making it suitable for large-scale bakeries and snack manufacturers. Its customizable pan and bowl sizes, combined with a powerful PLC touch screen, ensure streamlined production while maximizing flexibility for diverse output requirements. The fully automatic process reduces manual intervention, boosting productivity and consistency.

Advanced Automation & User-Friendly OperationExperience seamless functionality with a modern touch screen PLC control system and integrated automatic oil brushing. The user interface is designed for intuitive operation and easy monitoring, ensuring optimal control during production. Customizable temperature settings and an automatic process guarantee accurate, consistent wafer stick baking, while the integrated cooling conveyor ensures products are safely handled and ready for packaging.

Durability, Hygiene, and Safety GuaranteedBuilt entirely from food-grade stainless steel, this machine ensures long-term durability and high sanitation standards crucial for food processing. The equipment operates quietly, generating less than 65dB of noise, contributing to a comfortable work environment. With installation services and global after-sales support, users benefit from reliable operation and quick response to any technical needs.

FAQs of Wafer Stick Production Line Egg Roll Machine:

Q: How does the Wafer Stick Production Line Egg Roll Machine operate?

A: This machine is fully automatic, managed by a PLC touch screen control system. It automatically mixes, bakes, oils, cools, and conveys wafer sticks, significantly limiting manual input and optimizing efficiency throughout the process.

Q: What are the benefits of using this wafer stick machine for production?

A: Users gain increased productivity (up to 12,000 sticks/hour), consistent product quality, low noise operation, reduced labor requirements, and compliance with hygiene standards due to the machines food-grade stainless steel construction.

Q: When is the installation and after-sales service available?

A: Installation services can be arranged upon request. After-sales service is readily available, including access to overseas engineers who can address technical issues and provide ongoing machine support.

Q: Where is this machine ideally installed and used?

A: The machine is best suited for large-scale manufacturing facilities such as bakeries, snack factories, or food processing plants that require high-volume, consistent wafer stick production.

Q: What processes are integrated into the machines production line?

A: The system incorporates batter mixing, baking using electric heating tubes, automatic oil brushing, integrated cooling, and conveyance. Each process is automated for efficiency and uniformity.

Q: How can I customize the bowl or pan size for specific production needs?

A: Both the bowl and pan sizes can be tailored to the clients requirements at the time of ordering, allowing optimal alignment with individual production goals or spatial limitations.

Call Me Free

Call Me Free