Product Description

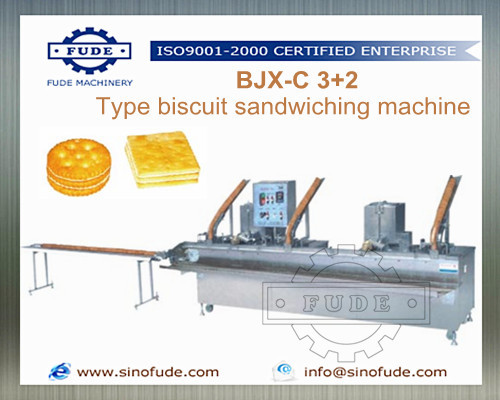

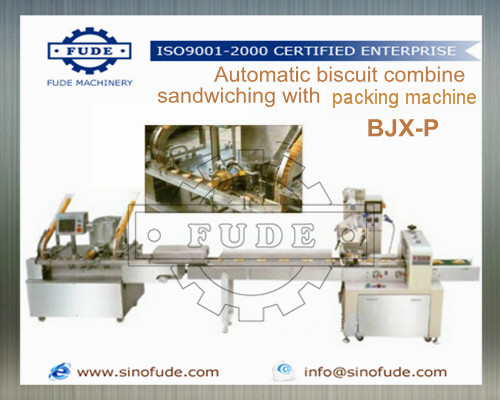

This biscuit processing line is an advanced equipment for making various kinds of biscuit, such as crisp biscuit, tenacity biscuit, sandwiching biscuit with chocolate or cream in the middle layer, etc..It is also an ideal equipment which can produce out good quality products with saving of both the manpower and the space occupied.

Technical parameters for Automatic biscuit production line :

Model | BBG250 | BBG400 | BBG600 | BBG800 | BBG1000 |

Capacity(KG/H) | 50-80 | 100-200 | 200-400 | 400-600 | 600-1200 |

REMARK:Actual capacity is base on the oven length,biscuit type,size and thickness |

Advanced Automation and EfficiencyThe FUDE BBG Series production line leverages state-of-the-art PLC control (Siemens/Mitsubishi) with an intuitive touch screen HMI for seamless operation. Automatic systems handle everything from greasing to stacking, reducing manual labor and increasing output consistency. The heavy-duty stainless steel construction enhances reliability, while customizable features let manufacturers optimize workflows for different product types and production scales.

Versatility for Your Manufacturing NeedsDesigned for flexibility, this multi-function line produces a variety of biscuitsincluding hard, soft, cookies, and crackerswith customizable thickness, size, and shapes. The machinery accommodates interchangeable moulds and cutters (rotary and wire-cut) to boost production diversity. With adjustable speed, mixing, and oven temperature, manufacturers enjoy precise control of recipe outcomes.

Comprehensive Support and ServiceFUDE provides installation services and after-sales support, including overseas engineers for set-up and training. Each line includes robust safety features, and operational guidance is available for staff. The lines modular design allows for tailored configurations, and its energy-efficient heating ensures lower operational costs over time.

FAQs of FUDE BBG series Automatic multi-function biscuit production line - With electric heating oven:

Q: How does the FUDE BBG biscuit production line optimize biscuit quality and consistency?

A: The fully automated PLC-controlled system, precision heavy-duty rollers, and customizable moulds ensure uniform thickness and shaping. Automatic greasing and stacking systems further enhance consistency throughout the production process.

Q: What types of products can be manufactured with this production line?

A: This line is capable of producing a wide range of biscuits, including hard and soft varieties, cookies, and crackers. Multiple shapes and sizes are achievable with interchangeable moulds and rotary or wire-cutters.

Q: When would installation and training be available for new buyers?

A: FUDE offers installation and training services immediately following delivery. Experienced engineers are available for overseas setup and staff training, ensuring a smooth start to production.

Q: Where can the production line be customized for unique production requirements?

A: Customization is available for oven length, conveyor width, control system (Siemens or Mitsubishi PLC), mould types, cutting mechanisms, and overall line dimensions to match specific plant layouts and output goals.

Q: What is the typical process flow on this biscuit production line?

A: The process begins with dough mixing (2080 rpm, 1030 min per batch), followed by sheet forming, cutting or moulding, automatic greasing, baking in an electric oven (max 300C), cooling, and ends with integrated stacking. Each step is fully automated for efficiency.

Q: How does using this automated line benefit industrial biscuit manufacturers?

A: Manufacturers benefit from enhanced productivity, consistent product quality, reduced manual intervention, lower energy consumption due to efficient electric heating, and the ability to rapidly switch between different biscuit types as required.

Q: What are the power and utility requirements for operating this biscuit line?

A: The line requires a three-phase 380V/50Hz electric power supply (customizable), an air compressor with 0.40.6 MPa capacity, and runs on 50250 kW, depending on the configuration chosen.