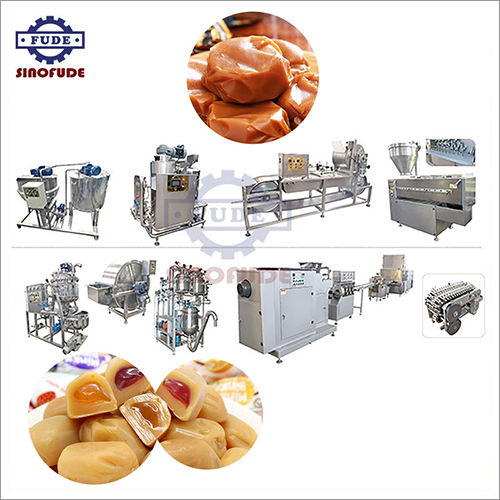

Product Description

Chewy Candy Production Line SPECIFICATIONS

| Model | CNT300/CYKL300 | CNT600/CYKL600A |

| Capacity | 300kg/h | 600kg/h |

| Candy weight | Shell: 7g (max), filling 2.5g(max) |

| Power | 48kw/380V | 60kw/380V |

| Steam Needed | 0.4~0.6MPa 400kg/h | 0.5~0.8MPa 600kg/h |

| Compressed Air | 0.6MPa, 0.5CBM/min | 0.6MPa, 1CBM/min |

| Length of Line | 16m | 20m |

| Machine Weight | 8000kg | 10000kg |

Efficient and Hygienic Candy ProductionThe CCPL-2200 boasts a fully enclosed stainless steel design combined with centralized automatic lubrication and integrated cleaning systems (CIP) for superior hygiene. Its automatic forming and PLC touch screen control ensure consistent candy quality and efficient operation. The cooling tunnel with adjustable temperature supports optimal soft candy production, meeting food safety standards while minimizing manual labor.

Flexible Operation and Easy InstallationBuilt for convenience, the modular construction of CCPL-2200 enables effortless installation, relocation, and maintenance. Operators benefit from the automated processes and adjustable conveyer belt speed, reducing downtime and increasing overall productivity. Designed for a range of candies, it adapts to various manufacturing requirements and packaging options.

FAQ's of Chewy Candy Production Line:

Q: How is the CCPL-2200 Chewy Candy Production Line installed and transported?

A: The CCPL-2200 features a modular design, making installation straightforward and allowing the equipment to be easily moved or relocated. Professional installation services are available to ensure safe setup and optimal operation at your facility.

Q: What types of candies can the CCPL-2200 produce?

A: This production line is suitable for manufacturing chewy candies, toffees, and other soft candy varieties. Its adjustable cooling tunnel and forming speed support a wide range of product textures and shapes.

Q: What is the cleaning process for this production line?

A: Cleaning is handled by a CIP (Clean-in-Place) system integrated into the machine, ensuring thorough, automated internal sanitation with minimal manual intervention. This supports hygiene and reduces downtime between production batches.

Q: When should maintenance be performed on the CCPL-2200?

A: Regular maintenance should be scheduled according to usage frequency and manufacturer guidelines. The system's centralized automatic lubrication and overload protection help minimize maintenance needs and protect core machine components.

Q: Where is the CCPL-2200 suitable for use?

A: The CCPL-2200 is suitable for commercial candy manufacturing environments, such as factories, export facilities, or supplier workshops, ideally operating in ambient temperatures between 0-40C.

Q: What are the operational requirements for the CCPL-2200?

A: It operates using electric power (380V/50Hz, three phase) and requires an air compressor with a minimum pressure of 0.6 MPa. Water consumption is approximately 150L/h, and only 1-2 workers are needed for monitoring and general supervision due to its high level of automation.

Q: How does the CCPL-2200 benefit manufacturers and distributors?

A: With high output rates, fully automatic forming, integrated packaging, and advanced safety features, the CCPL-2200 enables manufacturers and distributors to maximize efficiency, product consistency, and workplace safety while reducing labor costs.