Product Description

Two Lanes Biscuit Sandwiching Machine

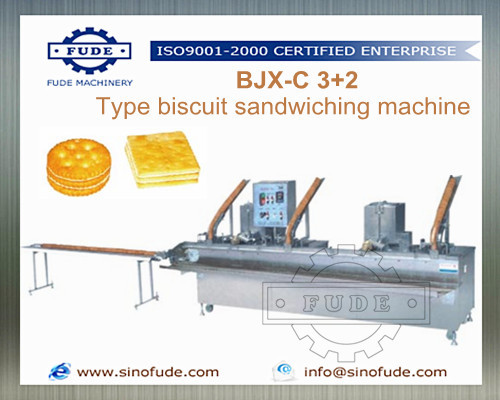

- BJX-B 2+1 two lanes biscuit sandwiching machine

- The machine is two lanes with function of one/two(option)flavor cream/jam/chocolate sandwiching in two biscuit.

Technical specification

- Capacity200~600 sandwiches/min.

- Biscuit size: Round (38~60mm, H:3~7mm); Square (LxW: 38~60mm; H:3~7mm)

- Power220V/50HZ/3kW;

- Machine size: 4200x900x1400mm

Innovative Dual Lane OperationWith independent control for each lane, this machine maximizes flexibility and efficiency. Adjust lanes individually to handle different biscuit types or production requirements. The synchronized biscuit feeding mechanism, guided by a vibratory feeder, ensures consistent alignment and high throughput, supporting manufacturers aiming for superior productivity in demanding environments.

Advanced Cream Filling PrecisionThe integrated volumetric control system delivers precise cream injection for every sandwich biscuit. Operators can easily adjust filling quantities, guaranteeing product uniformity and optimal taste experience. This feature significantly reduces the risk of waste and increases yield, helping your production operations remain both cost-effective and consistent.

Safety and Hygienic ExcellenceEquipped with advanced safety mechanisms like emergency stops, safety guards, and overload protection, the machine prioritizes operator safety. Its hygienic construction, with easy-to-clean surfaces and simple disassembly, enhances food safety and speeds up cleaning routines. These attributes make it an ideal solution for maintaining robust quality standards in any food processing facility.

FAQs of Two Lanes Biscuit Sandwiching Machine:

Q: How does the Two Lanes Biscuit Sandwiching Machine ensure precise cream filling?

A: The machine uses a precision volumetric control system, allowing operators to easily adjust cream volumes for consistent and accurate filling of each biscuit sandwich, enhancing product uniformity and reducing material waste.

Q: What safety features are incorporated in this sandwiching machine?

A: It is equipped with emergency stop buttons, safety guards, and overload protection to ensure safe operation for users. These measures minimize the risk of accidents during production and maintenance.

Q: When should you perform cleaning and maintenance on the machine?

A: Routine cleaning is recommended after each production cycle or batch to maintain hygienic standards. The machines hygienic design with easy-to-clean surfaces and removable parts streamlines this process.

Q: Where is this machine best utilized?

A: This biscuit sandwiching machine is ideal for use in bakeries, confectionery factories, and food processing plants that require high-speed, automated production of cream sandwich biscuits with stringent hygiene requirements.

Q: What is the process for adjusting biscuit and cream alignment on this machine?

A: The machine features automatic alignment of biscuits and cream, facilitated by its vibratory feeder and synchronized conveyor system. Lane width adjustments can be made easily through its computerized touchscreen PLC display.

Q: How can operating parameters be monitored or changed?

A: Operators can monitor and adjust parameters such as lane control, filling amount, and conveyor speeds using the touchscreen PLC display, providing intuitive operation and fine-tuned production control.

Q: What are the main benefits of using this industrial biscuit sandwiching machine?

A: Key benefits include high-speed, fully automatic production, precision cream filling, adaptable lane widths, reliable safety, and easy cleaningresulting in consistent quality, reduced downtime, and efficient biscuit manufacturing.

Call Me Free

Call Me Free