Product Description

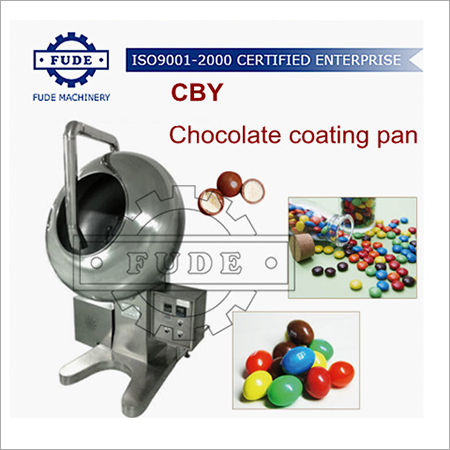

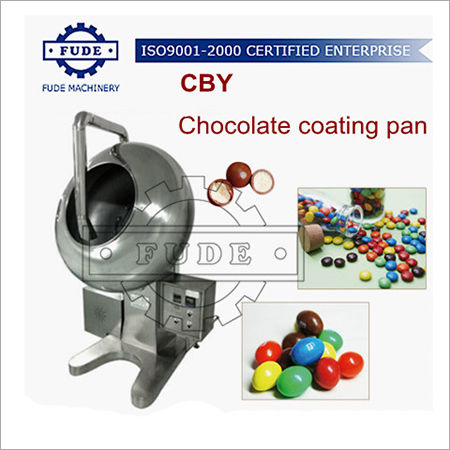

CBY600 Chocolate coating pan

Introduce:

The coating pan is used for coating and polishing chocolate,syrup,wax etc on grains products.

Main parameter:

| MODEL | CBY600 |

| Diameter (mm) | 600 |

| Capacity(kg/batch) | 15 |

| Rotary speed(r/min) | 36 |

| Motor power(kw) | 1.1 |

| Fan power(kw) | 0.15 |

| Heater power(kw) | 1 |

Efficient and Uniform Coating PerformanceThe CBY600 is engineered for consistent and smooth results, ensuring every batch achieves a glossy, professional finish. Its 600 mm stainless steel drum and 30 RPM pan speed facilitate thorough mixing of coatings, whether youre treating chocolates, nuts, or other edibles. The machines design optimizes coating efficiency and minimizes wastage, making it ideal for commercial use.

Safe, Quiet, and User-Friendly OperationPrioritizing both quality and safety, the CBY600 is equipped with overload protection, ensuring operational security during continuous runs. Its low-noise function creates a more comfortable working environment. The floor-mounted design, user-adjustable controls, and straightforward cleaning system allow seamless integration into existing production lines with minimal disruption.

FAQs of CBY600 Chocolate coating pan:

Q: How does the CBY600 Chocolate Coating Pan achieve a smooth, glossy surface on products?

A: The machines food-grade stainless steel drum rotates at 30 RPM, ensuring even distribution of coatings across each item, resulting in a uniform, glossy finish for chocolates, nuts, seeds, or pills.

Q: What types of products can be processed with this coating pan?

A: The CBY600 is suitable for coating and polishing a wide range of items, including chocolate products, confections, nuts, seeds, and pharmaceutical pills, making it versatile for various industries.

Q: When should I choose the air cooling or water cooling option for this machine?

A: Choose air cooling for most standard coating tasks. Opt for water cooling if you are processing large batches or heat-sensitive products, as it offers enhanced temperature control during operation.

Q: Where is the CBY600 commonly installed and what is the typical setup requirement?

A: This machine is floor-mounted and commonly installed in commercial candy, chocolate, or pharmaceutical production facilities. It only requires a stable, level floor space and access to 220V/380V electric power.

Q: What is the process for coating chocolate or candy with the CBY600?

A: Raw items are loaded into the drum, coating material is introduced, and the drums rotation ensures thorough mixing and coating. After a set period, the coated products emerge with a smooth, polished appearance.

Q: How does the overload protection feature benefit daily operation?

A: The overload protection system automatically stops the motor if excessive load is detected, preventing equipment damage and ensuring staff safety during intensive production cycles.

Q: What cleaning and maintenance steps are required for this machine?

A: Manual cleaning is required after each batch to maintain hygiene and performance. All contact parts are accessible and made from food-grade stainless steel, simplifying the cleaning process.

Call Me Free

Call Me Free