Product Description

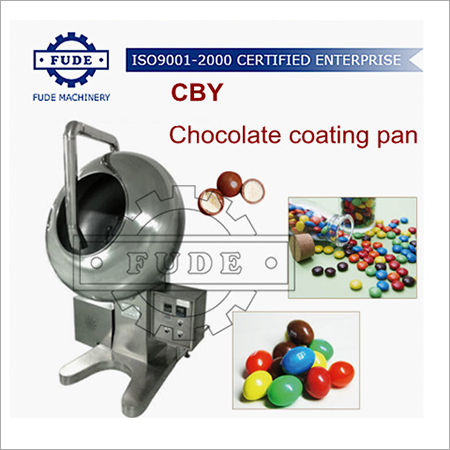

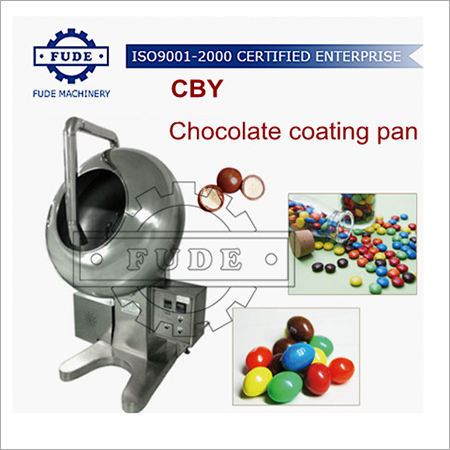

CBY800 Chocolate coating pan

Introduce:

The coating pan is used for coating and polishing chocolate,syrup,wax etc on grains products.

Main parameter:

| MODEL | CBY800 |

| Diameter(mm) | 800 |

| Capacity(kg/batch) | 30-40 |

| Rotary speed(r/min) | 36 |

| Motor power(kw) | 1.1 |

| Fan power(kw) | 0.15 |

| Heater power(kw) | 2 |

Uniform Coating PerformanceDesigned with an 800 mm rotary drum and adjustable tilt, the CBY800 delivers thorough, even chocolate or candy coating. The systems optimized drum speed aids in distributing coatings uniformly, ensuring each batch meets industrial quality standards. This results in glossy, market-ready products with consistent texture and appearance.

Flexible Operations and Easy MaintenanceSuitable for batch sizes ranging from 30 to 50 kg, the CBY800 supports frequent recipe changes thanks to its surface-washable drum and external fan-compatible cooling options. The integrated water spray system streamlines cleaning and minimizes downtime, while the sturdy stainless-steel construction guarantees long-lasting performance in high-demand environments.

User-Friendly Controls and SafetyThe pan operates via manual or semi-automatic controls, allowing operators to fine-tune coating parameters. Installation is floor-mounted for enhanced stability, and noise is reduced to less than 65 dB for a safer, more comfortable workspace. Its robust build and safety features make it ideal for food production lines prioritizing efficiency and hygiene.

FAQs of CBY800 Chocolate coating pan:

Q: How does the CBY800 ensure uniform coating of chocolates and nuts?

A: The CBY800 uses a large 800 mm rotary drum with an adjustable tilt angle (030) and a controlled drum speed of 30 rpm, which creates an optimal tumbling action. This motion facilitates even distribution of coatings over each item, resulting in a consistent finish for every batch.

Q: What types of products can I process with this coating pan?

A: The CBY800 is versatile and suitable for coating and polishing chocolates, candies, and various nuts. Its design accommodates a wide range of confectionery products, making it ideal for production lines requiring flexibility.

Q: When should I use the heating or cooling features during operation?

A: Use the 1.5 kW heating system when working with chocolate or any coating that requires temperature control for melting or fluidity. The external air or water cooling features should be engaged during or after coating to set and solidify the layer, ensuring optimal adhesion and finish.

Q: Where should the CBY800 be installed for optimal performance?

A: The CBY800 is a floor-mounted piece of equipment and should be placed in a well-ventilated, flat area with access to power (380V, 3-phase or 220V), and nearby water connections for the cleaning system. Proper space around the unit is recommended for maintenance and operator safety.

Q: What is the cleaning process for the CBY800 coating pan?

A: Cleaning is facilitated by an integrated water spray system, which allows surface washing and sanitation. The stainless-steel drums can be easily wiped down, and air or water cooling attachments help in rapid drying post-cleaning.

Q: How do the manual and semi-automatic controls benefit the operator?

A: Operators have the flexibility to adjust processing parameters according to batch requirements. Manual and semi-automatic options provide both hands-on control for customized batches and automated functionality for improved efficiency, enhancing ease of use and productivity.

Q: What are the main benefits of using the CBY800 coating pan in industrial production?

A: The CBY800 offers uniform coating, robust construction, large capacity (800 L), and easy cleaning, making it ideal for large-scale confectionery production. Its ergonomic features reduce noise and ensure operational stability, ultimately supporting high-quality, hygienic output for manufacturers and exporters.

Call Me Free

Call Me Free