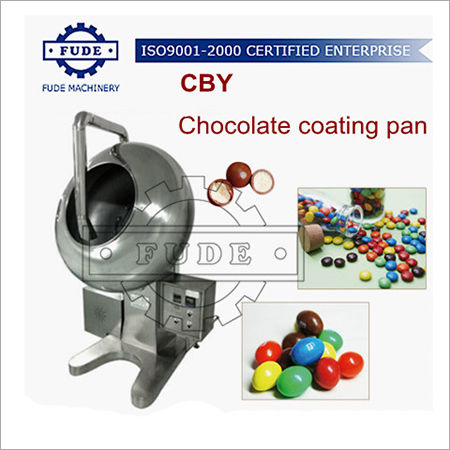

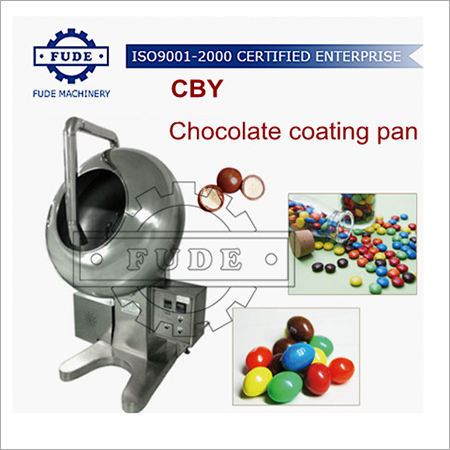

Product Description

Profile: FUDE MACHINERY supply the CBY Series coating pan, which is mainly used for ball shape, grain shape materials mixing, polishing, coating etc..in confectionery, pharmaceutical, or other light industry. Such as the chocolate bean, jelly bean, nuts coating, pills, etc.. This machine is mainly consists of frame body, worm and screw driving system, stainless steel pan, heater and fan (optional), controlling system. The pan is driving by worm wheel and motor. With the centrifugal effect the grains are rolling and attrition in the pan with other materials such as chocolate, sugar, glue materials etc..to be coated or polished.

More like tulip shape can be customized.

Small Chocolate Coating Pan is comprised of a motor, a mixing container made of steel, driving system, and a control panel. It is a type of entry level instrument that is suitable for startup bakery business due to its portable structure. This machine is utilized for coating chocolate on variety of confectionery items including mylikes, beans, nuts, almonds, & other dry fruits. It can also be used for spraying sugar syrup on candies & jellies.

Efficient Chocolate Coating SolutionDesigned for chocolate, nuts, and confectionery coating, this rotary pan offers controlled heating and smooth motion for uniform results. The stainless steel build and semi-automatic control simplify the coating process, supporting artisanal and commercial applications alike. Its compact, table-top design maximizes space while delivering consistent quality.

Compact Design and User-Friendly OperationWeighing just 3045 kg, the portable structure suits various environments. Manual cleaning and an easy-to-access control panel ensure straightforward maintenance. Overload protection and energy-saving features enhance both safety and efficiency during use.

FAQs of Small Chocolate Coating Pan:

Q: How is the Small Chocolate Coating Pan operated?

A: The pan operates with a semi-automatic control system using either a manual or panel controller. The geared electric motor drives the pan at a stable speed of 2832 RPM, making operation straightforward and safe.

Q: What process does the pan use to coat confectionery items?

A: This pan utilizes rotary motion with gentle heating from an electric heater to ensure a smooth, continuous coating of chocolate, nuts, or other confectionery items under atmospheric pressure. Air cooling helps set the coating evenly.

Q: When should manual cleaning be performed on the pan?

A: Manual cleaning is recommended after every batch or at the end of each production cycle to maintain hygiene and prevent cross-contamination between different confectionery products.

Q: Where is the Small Chocolate Coating Pan best installed?

A: Thanks to its compact and portable tabletop design, the pan is ideal for small chocolate shops, bakeries, and laboratory-scale confectionery production facilities. It can be easily relocated as required.

Q: What are the main benefits of using this pan for chocolate coating?

A: Users benefit from low noise operation, easy handling, energy efficiency, and reliable overload protection. The durable stainless steel finish also ensures longevity and facilitates cleaning.

Q: How much product can the pan process in a single batch?

A: The pan is capable of coating 35 kg per batch, making it suitable for small- to medium-scale production needs in confectionery settings.