Product Description

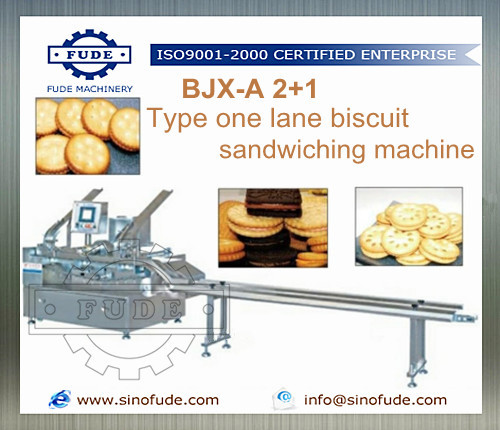

One Lane Biscuit Sandwiching Machine

- BJX-A 2+1 type one lane biscuit sandwiching machine

- The machine is single lane with function of one/two (option) flavor cream/jam/chocolate sandwiching in two biscuit.

Technical specification

- Capacity100~400 sandwiches/min.

- Biscuit size: Round (35~60mm, H:3~7mm); Square (LxW: 35~60mm; H:3~7mm)

- Power220V/50HZ/3kW (one flavor);5.5kW (two flavor)

- Machine size: 4200x900x1400mm (one flavor); 4600x1000x1450mm(two flavor)

Customizable Precision for Biscuit ProductionThis biscuit sandwiching machine allows for precise adjustments to both the size of the biscuit and the thickness of the cream filling, ensuring consistent product quality and adaptability for a range of recipes. The adjustable conveyor speed enhances control over your production output, and the PLC touch screen facilitates straightforward operation and monitoring.

Hygiene and Durability at Its CoreConstructed from food grade stainless steel, the sandwiching machine prioritizes hygiene and durability for long-term industrial use. The automatic lubrication system and robust frame reduce maintenance demands, while the metallic finish and thoughtful design add a modern look to any production line.

FAQs of One Lane Biscuit Sandwiching Machine:

Q: How does the One Lane Biscuit Sandwiching Machine operate in a production line?

A: The machine automates the process of placing cream between two biscuit halves by using adjustable conveyors and a PLC-controlled system, ensuring efficient and precise assembly for industrial-scale biscuit production.

Q: What features allow customization for different biscuit products?

A: You can adjust both the biscuit size and cream thickness on the machine, allowing quick adaptation to different product specifications. The conveyor speed is also adjustable to match specific production requirements.

Q: When is servicing required, and how is after-sales support handled?

A: Routine maintenance is minimal thanks to the automatic lubrication system, but should any issues arise, engineers are available for servicing overseas to ensure minimal downtime.

Q: Where can this machine be used in the food manufacturing sector?

A: It is ideally suited for biscuit production lines and confectionery industries where consistent, high-volume sandwiching is required.

Q: What is the process for loading ingredients and starting production?

A: Operators load cream filling into the 40 L stainless steel hopper and place biscuit halves on the infeed. The computerized system then manages assembly, with settings adjusted via the PLC touch screen.

Q: How does this machine benefit manufacturers compared to manual methods?

A: It ensures higher consistency, faster output, and hygiene, while reducing labor costs and manual errors, which results in efficient large-scale production.

Q: Is compressed air required for operation and what are the power specifications?

A: Yes, the machine operates with a compressed air pressure of 0.6 MPa and requires an electric supply of 2.5 kW, suitable for either single or three-phase power setups.

Call Me Free

Call Me Free