Product Description

Automatic Mufti-function Biscuit Production Line

Model | BBG250 | BBG400 | BBG600 | BBG800 | BBG1000 |

Capacity (KG/H) | 50~80 | 100~200 | 200~400 | 400~600 | 600~1000 |

Remark: Actual capacity is base on oven length, biscuit type, size and thickness. |

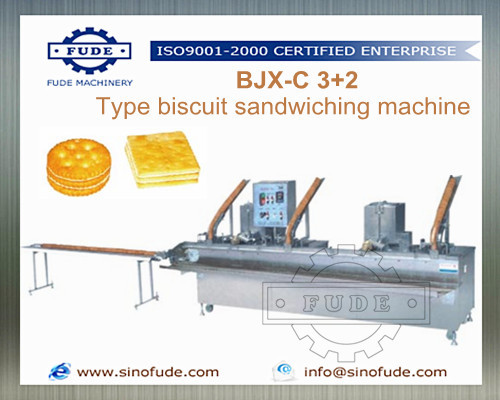

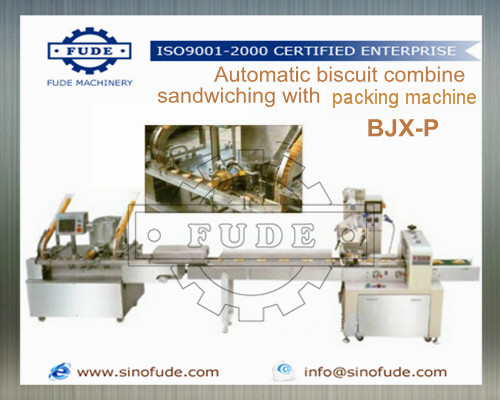

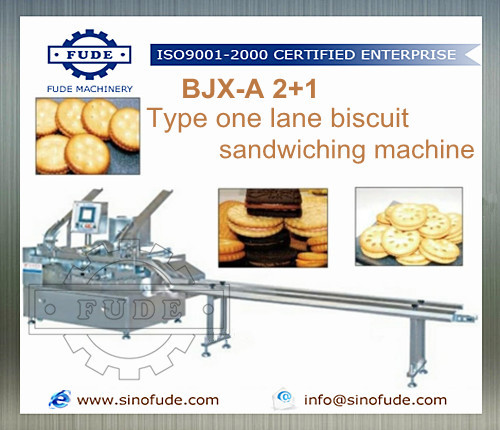

Versatile Biscuit Production CapabilitiesThe production line is designed to handle a broad spectrum of biscuit typeshard, soft, cookies, and sandwich biscuitsusing advanced mould forming, rotary, and wire-cut technologies. It supports customizable sizes ranging from 30mm to 80mm and multiple shapes. Flexible operation allows for single or double production lines, optimizing output according to your requirements.

Automated Controls for Consistent QualityEquipped with a touch screen PLC panel and automated recipe management, the system ensures precise control over every stage of the process. Remote monitoring capabilities make it easy to oversee production and make adjustments, supporting a robust output rate of up to 98%. Integrated dehumidifying and temperature control up to 300C guarantee consistent product quality.

Energy Efficient and Safe OperationEnergy-saving features and a low-noise, highly efficient design reduce operating costs and create a comfortable work environment. Centralized automatic lubrication, semi-automatic cleaning, overload protection, and emergency stop systems enhance machine safety and lifespan, ensuring reliable day-to-day operation.

FAQs of Automatic Mufti-function Biscuit Production Line:

Q: How does the installation service for the Automatic Multi-function Biscuit Production Line work?

A: Installation service is available and includes on-site setup by experienced engineers. They handle the assembly, calibration, and initial programming to ensure your production line operates smoothly from day one.

Q: What types of biscuits and shapes can be produced with this system?

A: The line supports the manufacture of hard biscuits, soft biscuits, cookies, and sandwich biscuits. Shapes can be customized to round, square, rectangle, or other designs as required, with size options ranging from 30mm to 80mm.

Q: When should the semi-automatic cleaning system be operated for optimal hygiene?

A: It is recommended to run the semi-automatic cleaning system at regular intervals, such as at the end of daily shifts or after switching between different recipes, to maintain food safety and equipment performance.

Q: Where can this biscuit production line be effectively utilized?

A: This machine is ideal for large-scale biscuit factories, food processing plants, and industrial bakery setups. Its robust design and capacity make it suitable for high-demand manufacturing environments.

Q: What is the process flow for producing biscuits on this line?

A: The process starts with mixing ingredients (wheat flour, sugar, fats, water, etc.) at variable speeds, followed by dough forming, shaping (mould, rotary, or wire-cut), baking in a tunnel oven (electric/gas/diesel), cooling via an 8,000mm conveyor, and finally packaging.

Q: How does the automated recipe management benefit production?

A: Automated recipe management ensures consistency in taste and quality by precisely controlling ingredient ratios and baking parameters. It streamlines production changeovers, reduces errors, and saves time during recipe customization.

Q: What makes this production line energy efficient and safe?

A: The system incorporates energy-saving features, centralized automatic lubrication, an emergency stop, overload protection, and low-noise operation. These elements reduce energy costs, enhance worker safety, and extend the machinerys operational lifespan.

Call Me Free

Call Me Free