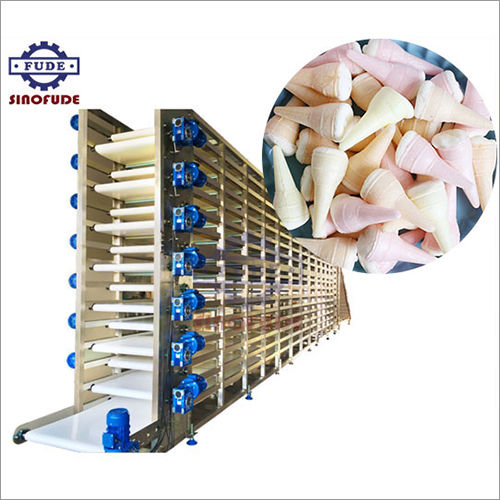

Product Description

Automatic Drying System SPECIFICATIONS:

| Model | TMHT600 | TMHT900 | TMHT1200 |

| Capacity (kg/h) | 60~100 | 150~200 | 300~500 |

| Cutting length (mm) | 10~800 (Extrude and Cut Type) |

| Steam consumption (kg/h) Steam pressure (kg/h) | 250 0.2~0.6 | 400 0.2~0.6 | 500 0.2~0.6 |

| Electric power needed | 35kW/380V | 45kW/380V | 55kW/380V |

| Compressed air needed. Compressed air pressure | 0.8m3/min 0.6-0.8MPa | 1m3/min 0.6-0.8MPa | 1.5m3/min 0.6-0.8MPa |

| Gross weight (kg) | 6000 | 8000 | 10000 |

| Length of the line(m) | 30 | 35 | 40 |

Efficient Industrial DryingHarness the power of a fully-automatic drying tunnel that merges hot air recirculation, integrated cooling, and computerized controls for maximized throughput. With stainless steel construction and insulation, this floor-mounted system ensures consistent performance while protecting both product quality and operator safety.

Advanced Safety and Easy MaintenanceSafety is paramount, thanks to overheat and overload protection features. Transparent inspection doors and easy-access panels simplify preventive maintenance and visual monitoring, reducing downtime and enhancing operation reliability for demanding industrial environments.

Versatile Applications Across IndustriesDesigned for versatility, this drying tunnel meets the rigorous demands of food, pharmaceutical, chemical, and textile operations. Automatic humidity sensors and PLC automation adapt to varied production requirements, optimizing drying conditions to deliver superior results regardless of application.

FAQ's of Automatic Drying System:

Q: How does the hot air recirculation technology improve drying efficiency in the Automatic Drying System?

A: The hot air recirculation technology continuously circulates heated air within the tunnel, promoting uniform heat distribution and moisture removal. This reduces drying time, minimizes energy consumption, and ensures even drying of products across both zones.

Q: What safety mechanisms are integrated into the system?

A: The system features overheat and overload protection to safeguard the unit and processed materials. These mechanisms automatically shut off or adjust the system during unsafe conditions, reducing the risk of damage and ensuring reliable operation.

Q: When and where is this drying tunnel best utilized?

A: This equipment is ideal for industrial drying needs in sectors such as food processing, pharmaceuticals, chemicals, and textiles. It is floor-mounted, making it well-suited for production lines in factories and processing plants.

Q: What steps are involved in maintaining the Automatic Drying System?

A: Maintenance is streamlined with easy-access panels for periodic checks and cleaning. The transparent inspection doors facilitate quick visual inspections, and the robust stainless steel build ensures longevity with minimal servicing required.

Q: How does the system control humidity during the drying process?

A: An automatic humidity sensor system constantly monitors and adjusts the internal environment, maintaining optimal moisture levels. This results in consistent drying outcomes for various products and protects product quality.

Q: What are the benefits of choosing this conveyor-type drying tunnel?

A: Key advantages include high energy efficiency, low noise levels, corrosion protection, a high processing capacity (500-800 kg/hr), easy operation via a computerized PLC system, and adaptability for multiple industry sectors.

Q: How is the drying process monitored and adjusted?

A: Monitoring and adjustment are handled through the PLC-controlled system, transparent inspection doors allow direct observation, and operators can adjust conveyor belt speed (0.5 to 5 m/min) and temperature (ambient to 120C) to suit specific drying requirements.

Call Me Free

Call Me Free