Product Description

Full Automatic Deposited Marshmallow Production Line SPECIFICATIONS:

| Model | TMHT600D | TMHT900D | TMHT1200D |

| Capacity (kg/h) | 60~100 | 150~200 | 300~500 |

| Depositing Speed (n/min) | 15~45 (Deposited Type) |

| Steam consumption (kg/h) Steam pressure (kg/h) | 250 0.2~0.6 | 400 0.2~0.6 | 500 0.2~0.6 |

| Electric power needed | 35kW/380V | 45kW/380V | 55kW/380V |

| Compressed air needed. Compressed air pressure | 0.8m3/min 0.6-0.8MPa | 1m3/min 0.6-0.8MPa | 1.5m3/min 0.6-0.8MPa |

| Gross weight (kg) | 6000 | 8000 | 10000 |

| Length of the line(m) | 30 | 35 | 40 |

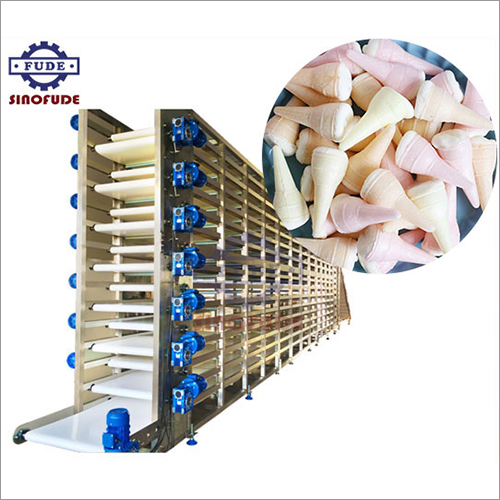

Versatile Marshmallow Forming CapabilityThe servo-driven piston depositor allows for the formation of various marshmallow shapes, including round, twisted, filled, and tailored designs. Its precision ensures consistent product size and shape, essential for brand uniformity in large-scale confectionery manufacturing.

High-Grade Material and Efficient CleaningFabricated with 1.5-3 mm food-grade stainless steel and equipped with a PU food-grade belt, the line guarantees food safety and robustness. The automated CIP (Clean-In-Place) system simplifies maintenance, minimizing downtime and supporting strict hygiene standards.

Advanced Control and ProductivityUtilizing a PLC touch screen, operators can easily manage all production parameters. The line's fully automated nature, cooling tunnel integration, adjustable conveyor speed, and forming speed (35-55 n/min) ensure high-capacity output and operational reliability.

FAQ's of Deposited Marshmallow Production Line:

Q: How does the servo-driven piston depositor improve marshmallow production?

A: The servo-driven piston depositor enables precise and consistent depositing, ensuring uniform shape and size of marshmallows-whether round, twisted, filled, or custom-designed-while enhancing production efficiency and reducing product variability.

Q: What is the process for cleaning the marshmallow production line?

A: The line utilizes a Clean-In-Place (CIP) system, which thoroughly cleans all internal surfaces without disassembly. Operators initiate the cleaning cycle via the PLC touch screen, streamlining hygiene maintenance between production batches.

Q: How many operators are required to run this production line, and what skills are necessary?

A: Only 2-3 operators are needed thanks to its fully automated design and PLC touch-screen controls. Basic technical understanding of machinery and familiarity with food-grade equipment are beneficial for optimal operation and supervision.

Q: What raw materials can be used in this marshmallow production system?

A: The line is suitable for processing sugar, glucose syrup, gelatin, water, flavors, and colors. All these ingredients are compatible with the system, ensuring the production of high-quality marshmallows.

Q: When is the cooling tunnel used during production, and what are its benefits?

A: After depositing, marshmallows pass through the integrated cooling tunnel, which works at 5-10C. This rapidly sets and stabilizes the products, preserving their shape and texture while improving process speed and quality.

Q: Where is this production line most effectively utilized?

A: This marshmallow production line is ideal for use in industrial confectionery factories, especially by manufacturers, exporters, and suppliers seeking large-batch, uniform marshmallow production with customizable shape options.

Q: What is the minimum order quantity for this marshmallow production line?

A: The minimum order quantity for the Deposited Marshmallow Production Line is one set, making it accessible whether you are upgrading facilities or starting a new confectionery manufacturing unit.