Product Description

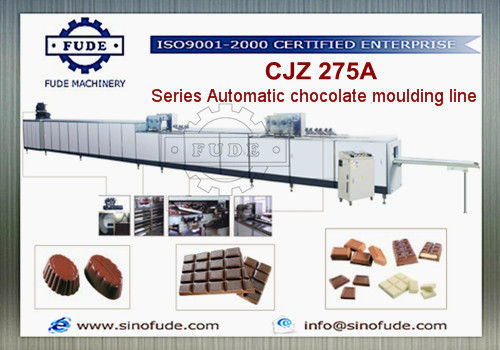

Chocolate Moulding Machine

Owing to our customization facility and rich domain expertise in this domain, we are engaged in manufacturing and exporting Chocolate Moulding Machine. These machines are engineered by our expert professional using supreme quality materials. Available in a wide range of specifications, these moulding machines are offered to our clients at unbeatable prices. Embedded with finished products conveyor, vibration, cooling tunnel and demoulding unit, Chocolate Moulding Machine is widely used for making chocolate.

Features:

- Easy installation

- High performance

- Supreme quality

Further Details:

single color, filled chocolate with cream, nuts, grains etc.The machine is consists of mould heating. etc.

Main parameter:

Model | Capacity (moulds/min) | Power KW | Mould Qty pcs | Weight (KG) |

CJZ275/320 | 10-15 | 7.47 | 200 | 500 |

Comprehensive Automation and PrecisionThe CJZ275 Chocolate Molding Machine embraces full automation, utilizing a PLC touch screen for precise operational control. This ensures meticulous deposit of chocolate for various shapes, supported by the adjustable conveyor and electric heating system. Whether youre producing bars, balls, or complex forms, the machines robust design and versatility guarantee uniform results each cycle.

Efficient Cooling and Energy ManagementEquipped with an integrated cooling tunnel and automatic temperature controls, the CJZ275 maintains optimal conditions for chocolate setting and texture. Its energy-efficient power consumption (18 kW) and low-noise operation ensure both high-output manufacturing and a comfortable working environment, while the adjustable air compressor and belt speed fine-tune production requirements.

FAQs of CJZ275 Chocolate Molding Machine:

Q: How does the CJZ275 Chocolate Molding Machine operate?

A: The CJZ275 operates fully automatically via a computerized PLC touch screen, enabling users to control temperature, depositing nozzles, cooling tunnel, and conveyor speed. Simply load chocolate mixture, select your mold and parameters, and the machine manages the entire molding, cooling, and demolding process.

Q: What types of chocolates can the machine produce?

A: This machine is versatile and can create bars, tablets, balls, and other custom-shaped chocolates. The high-precision depositing nozzles and adaptable mold plate make it suitable for various industrial chocolate products.

Q: When should I consider using the CJZ275 for my production line?

A: If your production requires high efficiency, stable performance, and low noise in making a diverse range of chocolate shapes for industrial quantities, the CJZ275 is an excellent choice. Its capacity and automation are ideal for scaling up manufacturing operations.

Q: Where can the CJZ275 be installed, and is installation support provided?

A: The CJZ275 is designed for industrial settings and is typically installed in chocolate manufacturing facilities. Professional installation service is available, and engineers can be dispatched internationally to assist with setup and training.

Q: What is the process for adjusting the molding and cooling parameters?

A: All key parameters, such as tunnel working temperature (0~10C), conveyor speed (up to 3.5 m/min), and heating settings, are adjusted via the PLC touch screen. This allows for easy customization to maintain optimal conditions for every chocolate product type.

Q: How does using this machine benefit chocolate manufacturers?

A: Manufacturers benefit from high output (up to 275 kg/h), precise and consistent product quality, energy efficiency, stable and low-noise operation, and minimal manual intervention. The included after-sales service and sturdy wooden case packaging further ensure smooth, reliable operation and transport.

Q: What after-sales services are available for the CJZ275?

A: Engineers are available to provide machinery servicing abroad, and comprehensive after-sales support is offered to help maintain machine performance and resolve technical issues promptly.