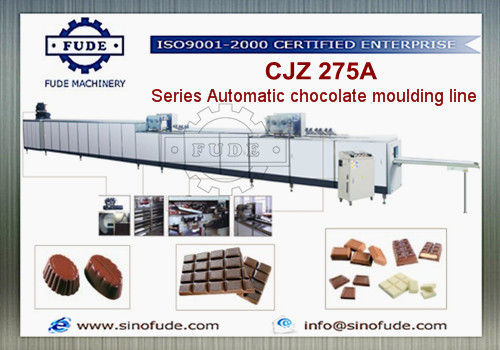

Product Description

Automatic chocolate moulding line

Introduce:

The CJZ275A series chocolate moulding line has the fuction of one shot,double shot,triple shot,shell chocolate making etc,it is an ideal equipment to make different types of chocolate products.

Main parameter

Model | Capacity (moulds/min) | Power KW | Mould Qty pcs | Weight (KG) | Machine size mm |

CJZ275A | 10-15 | 19 | 280 | 3500 | 16000 x 1000 x 1800 |

CJZ275A-2 | 10-18 | 23 | 330 | 4300 | 17000 x 1000 x 2300 |

CJZ275A-3 | 10-20 | 31.5 | 410 | 5200 | 17000 x 1000 x 3350 |

CJZ275A-T | 6-12 | 45 | 410 | 6500 | 15420 x 5270 x 2100 |

Flexible, High-Performance Chocolate ProductionWith customizable layout and mold options, the 275A Automatic Chocolate Molding Line adapts seamlessly to various production environments. It is engineered to deliver high efficiency and consistent quality, making it an ideal solution for manufacturers seeking scalability and reliable results.

Comprehensive Safety and AutomationFull safety enclosure, an advanced alarm system, and PLC touch screen controls deliver maximum operational safety and ease of use. The integrated emergency stop and quick-change mold design (less than 5 minutes) ensure superior workplace safety and high productivity.

FAQs of 275A Automatic Chocolate Molding Line:

Q: How does the automatic mold washing system work on the 275A Chocolate Molding Line?

A: The automatic mold washing system thoroughly cleans molds as part of the production cycle, helping maintain hygiene and consistent product quality without manual intervention. This feature saves labor time and minimizes production downtime.

Q: What are the benefits of using an electric heating source with five heating zones?

A: Electric heating with five distinct zones ensures precise temperature control throughout the molding process, which helps in producing chocolate with uniform texture and appearance. This setup also enables energy efficiency and operational consistency.

Q: When is the best time to perform mold changes, and how long does it take with this machine?

A: Mold changes can be performed at any point when a product switch or mold variation is needed. With the 275A line, mold changes take less than 5 minutes, minimizing downtime and improving operational flexibility.

Q: Where can the 275A Molding Line be installed, and is installation assistance available?

A: The production lines flexible, customizable layout means it can be installed in various plant environments. Professional installation services are available to ensure proper setup and smooth integration into existing systems.

Q: What processes are automated in this chocolate molding line?

A: Key processes such as chocolate depositing, mold transport, integrated cooling, and automatic mold washing are fully automated. This results in higher efficiency, reduced manual labor, and consistent product output.

Q: How can production speed and cooling be adjusted for different chocolate types?

A: The conveyor belt speed is adjustable up to 10 m/min to accommodate different production volumes and chocolate types. The integrated cooling tunnel, also adjustable, ensures the chocolate sets optimally under varying conditions.

Q: What are the primary advantages of using the 275A Automatic Chocolate Molding Line for industrial production?

A: Users benefit from high efficiency, rapid mold changes, low noise operation (80 dB), comprehensive safety features, and easy control via the PLC touch screen. Its robust stainless steel construction and customizable options further enhance productivity and durability.

Call Me Free

Call Me Free